K-Line Trailers: An Ergonomics Success Story

Controlling the risks

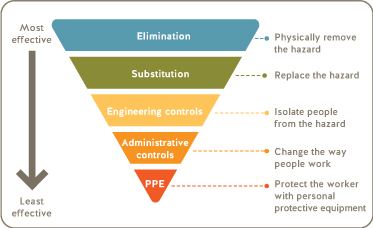

The Regulation requires employers to eliminate the risk of MSIs to workers or, if that is not practicable, to minimize the risk.

K-Line Trailers recognized the importance of following the hierarchy of controls. They understood that relying on worker training was not as effective at controlling MSI risk factors as controls that eliminated the hazard or reduced the risk through changes in the design. They also learned that not all suggested interventions worked as intended, so they saw the need to monitor and evaluate each intervention and to move on quickly to another option if it failed.

Some of the controls the SRT implemented according to the hierarchy of controls are described below:

Elimination

Workers were experiencing discomfort in the hands, wrist, shoulders, and neck from frequent hand tool use. The most challenging of these tasks was using an air-powered drill to drill through steel trailer chassis for the installation of mechanical components.

Engineering was consulted, which led to holes and cut-outs being added to the engineering drawings. Now, many of the holes are burned into the steel in pre-production using a CNC plasma table and access to hard-to-reach locations has improved with cut-outs.

Not only did this effort eliminate the need for much of the drilling, it has improved production speed.

Substitution

Workers had to hand polish aluminum to fix scratches and clean aluminum pieces. This repetitive task put strain on the shoulders, neck, and arms. After further investigation, consultation with suppliers, numerous trials, and training, it was determined that an electrically powered tool could be substituted and used for most of the work; the hand pad was only required for the final finishing. This process of substituting a powered tool eliminated the majority of the hand polishing.

Engineering controls

In many of the departments at K-Line Trailers, workers needed to reach up or over the objects being worked on. For example, welders reported shoulder and upper arm issues related to the force and duration needed to complete welds down the vertical side of workpieces. K-Line Trailers explored ways to reduce the weight of the welding whip and decided to trial the use of a commercially available tool balancer.

While it was a viable solution, a related challenge was where to attach the balancer. The in-house solution K-Line Trailers developed was to fabricate a special attachment so the tool balancer could be placed at a point on the box above where the worker was welding. With this engineering control, the weight of the whip held by the welder was less than 1 lb.

Administrative controls

K-Line Trailers found that sometimes interventions came to mind while discussing another issue. Such a situation occurred in the discussion about hand polishing aluminum pieces (see “Substitution” above). The aluminum pieces were stored outside on racks and were getting marked by weather and frequent handling.

One solution identified was to reduce inventory so material spent less time in storage outside. Another solution was to give the workers who would be removing the material from storage the responsibility for placing the pieces in storage, creating an incentive to minimize contact and scratches while doing so. These simple changes made notable improvements in the amount of polishing needed.

Read more

We're here to help

For resources, please visit worksafebc.com/ergonomics. If you have questions about ergonomics or human factors, or need help managing the risk of MSI in your workplace, please contact us at HumanFactors@worksafebc.com

|