| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Understanding the vibration levels of different handheld power tools

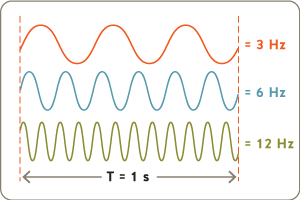

Vibration is caused by a moving object. Two important physical characteristics when evaluating the risk of health effects or discomfort associated with exposure to vibration are acceleration and frequency. In basic terms, acceleration — also known as the vibration level — is the measure of how fast the object is moving. The faster the object moves, the higher the acceleration or vibration level. In terms of vibration, acceleration is measured in m/s2. Frequency — also known as the number of cycles per second — is the measure of how many times the object is moving or oscillating back and forth. The faster an object is oscillating, the higher the frequency; the slower it is oscillating, the lower the frequency. In terms of vibration, frequency is measured in Hertz (Hz). To better understand acceleration and frequency, think of waves lapping on the shore. The speed with which the waves hit the shore is analogous to the acceleration and the number of waves hitting the shore during a set period of time is the frequency.

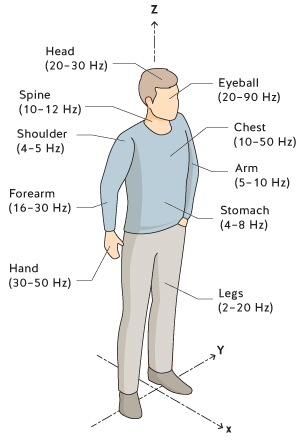

Thinking about vibration in this way may help to understand the risk of hand-arm vibration (HAV). The faster a wave hits the shore, the more damage it can cause. In other words, the faster the wave, the greater the risk. This premise translates directly to vibration: tools with higher acceleration or vibration levels result in a higher risk of adverse health outcomes. In terms of frequency, however, even though more waves that hit the shore may mean more potential damage, this can’t be directly translated to vibration. Each part of the body is susceptible to a vibration of a different frequency. For example, legs are most susceptible to vibration of 2-20 Hz, the stomach to 4-8 Hz, the hand to 30-50 Hz, and the arm to 5-10 Hz (see graphic below). This means that exposure to vibrating objects that oscillate in the frequency range to which the hand and arm are most susceptible result in the highest risk of adverse health effects from HAV.

Assessing the risk Per section 7.11(a) of the Occupational Health and Safety (OHS) Regulation, an employer must ensure that workers are not exposed to HAV in excess of the limits specified in the American Conference of Governmental Industrial Hygienists (ACGIH) publication, Threshold Limit Values and Biological Exposure Indices. Table 1: Summary of WorkSafeBC vibration exposure limits

The 5.0 m/s2 exposure limit is the maximum vibration level that a worker can be exposed to averaged over the course of an 8-hour shift. This means that a worker may be exposed to vibration in excess of 5.0 m/s2 as long as the duration of exposure is less than 8 hours. For example, a worker can operate a tool that exposes them to a vibration level of 10.0 m/s2 for up to 2 hours of an 8-hour shift. If the worker doesn’t operate any more tools that result in vibration exposure during the remainder of their shift, they will not have been overexposed to vibration. The 5.0 m/s2 exposure limit does not represent a boundary between safe and unsafe exposure and therefore, it is good practice and more protective for workers to take precautions before exposure reaches the exposure limit. This can be done by using 2.5 m/s2 as a guideline vibration level. When exposure reaches 2.5 m/s2, you may consider conducting a vibration risk assessment, educating workers about the risk and potential adverse health effects of exposure to HAV and take steps to reduce exposure by implementing control measures. If handheld power tools or hand-guided equipment are used at your workplace, you should conduct a risk assessment to help you determine the level of risk associated with vibration exposure. When determining the risk, consider the following elements:

There are three ways to find the vibration value for a tool:

Vibration measurement The best way to determine the vibration levels of the tools at your workplace is to hire a consultant or perform the measurements yourself following the methods of ISO Standards 5349-1:2001 and 5349-2:2001. There are two main quantities used to measure and represent HAV: aRMS and A(8). The aRMS value is the level of vibration generated by a particular piece of equipment and is determined by a short-term measurement. The aRMS is typically the same as the HAV value that is reported by equipment manufacturers. The A(8) value is the vibration exposure level averaged over 8-hours. The A(8) can be calculated or directly determined using a full-shift measurement The tables below provide a summary of aRMS and A(8) values for landscapers as measured by WorkSafeBC. Table 2: Short-term vibration measurements of landscaping tools and equipment, aRMS measurements

Table 3: Full-shift vibration exposure for landscapers, A(8), which is directly comparable to WorkSafeBC 5.0 m/s2 exposure limit

Vibration database Vibration databases based on real-world measurements are the second-best option. There are many databases that provide the vibration levels associated with various tools. You can conduct a search online to find these databases. Table 4: Summary of vibration levels and maximum allowable exposure duration

Note: There are many factors that affect the vibration level generated by a tool. Some of these factors include the tool make and model, the attachment used (e.g., grinding disc versus polishing disc), and work surface (e.g., wood versus metal). The values presented in the table should be used as guidance only. Manufacturer-reported vibration level Manufacturers determine the vibration level of their equipment in a laboratory setting using brand new equipment and attachments. Because of this, their reported vibration levels typically underestimate the vibration levels found in real-world use. Additionally, the manufacturer reported vibration levels are typically only for a single use scenario and may not represent all of the real-world use scenarios. For example, a manufacturer may report the vibration level for using their drill on a concrete surface but workers may use this drill on steel. Manufacturer-reported vibration levels are better suited to comparing one tool to another. For example, when purchasing new equipment, it’s always a good idea to review the manufacturer levels of the equipment you’re considering and choose the option that generates the lowest level of vibration. There is no requirement for manufacturers to report vibration levels of their equipment and therefore you may not even be able to find this information. Table 5: Comparison of manufacturer-reported vibration level and measured vibration level

Read more We're here to help For resources, please visit worksafebc.com/ergonomics. If you have questions about ergonomics, human factors or need help managing the risk of MSI in your workplace, please contact us at HumanFactors@worksafebc.com | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WorkSafeBC, PO Box 5350 Stn Terminal, Vancouver BC V6B 5L5